FibreGY Project: Next Generation Offshore Platforms with Composite Materials

Compass Ingeniería y Sistemas would like to highlight our participation and contribution to the development of important technological innovation milestones in the marine renewable energy sector. These achievements were reached within the framework of the European R&D project FIBREGY (2021 – March 2024), funded by the Horizon 2020 programme of the European Union, and carried out together with a leading consortium of companies and research centres from all over Europe.

An initiative to revolutionize marine renewable energy

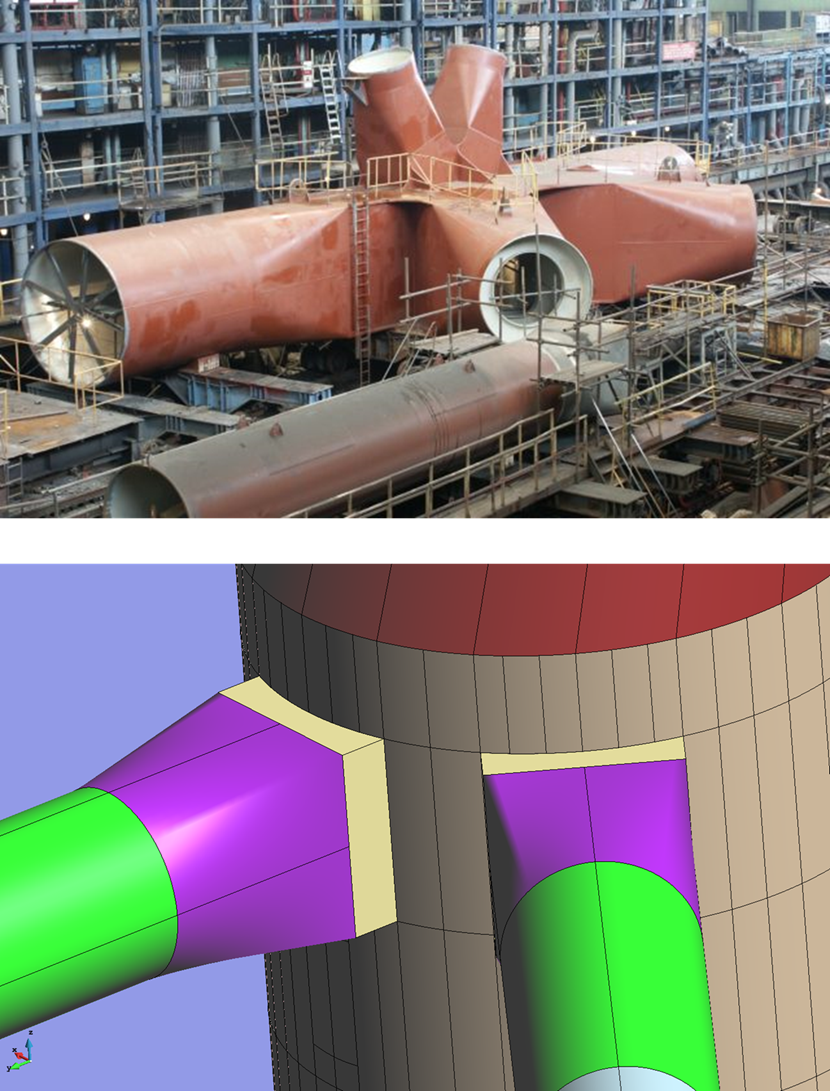

The FIBREGY project was a cutting-edge European initiative designed to revolutionise the marine renewable energy sector. Its strategic mission has been the design and verification of the extensive and reliable use of fibre reinforced plastics (FRP) in key components of the floating offshore structure, materialising the steel-FRP hybridisation of the W2Power (Enerocean) wind turbine’s resistant structure.

Advantages of composite materials over steel

The advances and results have been outstanding, generating new knowledge and real data that can be used in the next generation of wind and tidal energy platforms. The study of composite materials is evident, as traditional materials, such as steel, are heavier and susceptible to corrosion, which is a high cost in the marine environment.

A holistic approach along the entire value chain

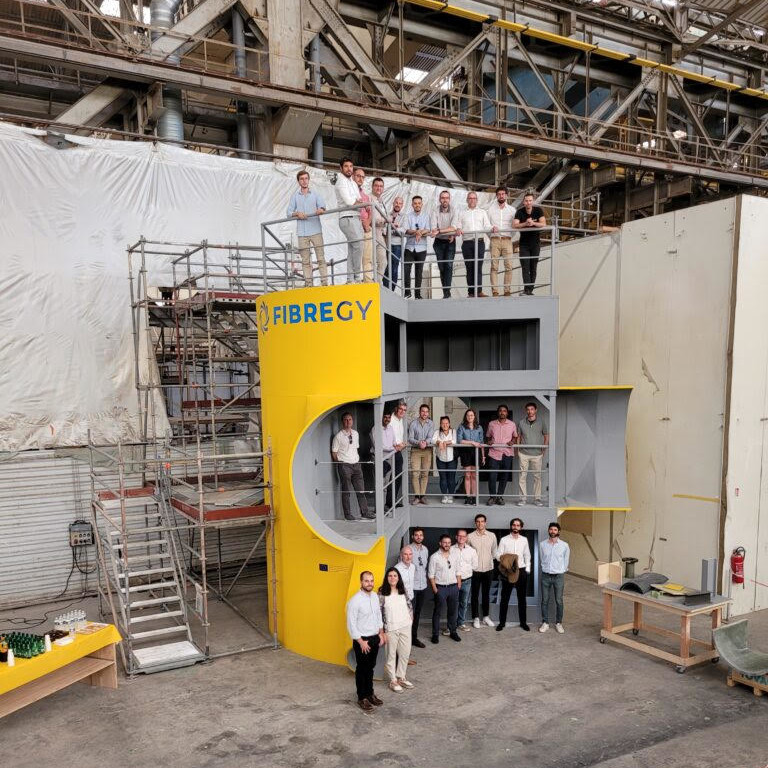

The project addresses the entire value chain: from the qualification of innovative materials, the development of new calculation methodologies, efficient production processes and the validation of solutions through prototypes and full-scale demonstrators.

COMPASSIS’ technical leadership in WP3 and WP4 packages

In this context, COMPASSIS has technically led the package:

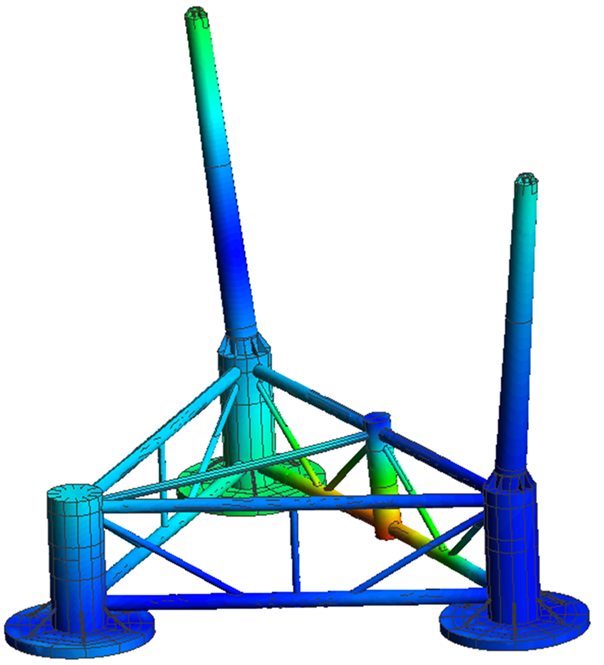

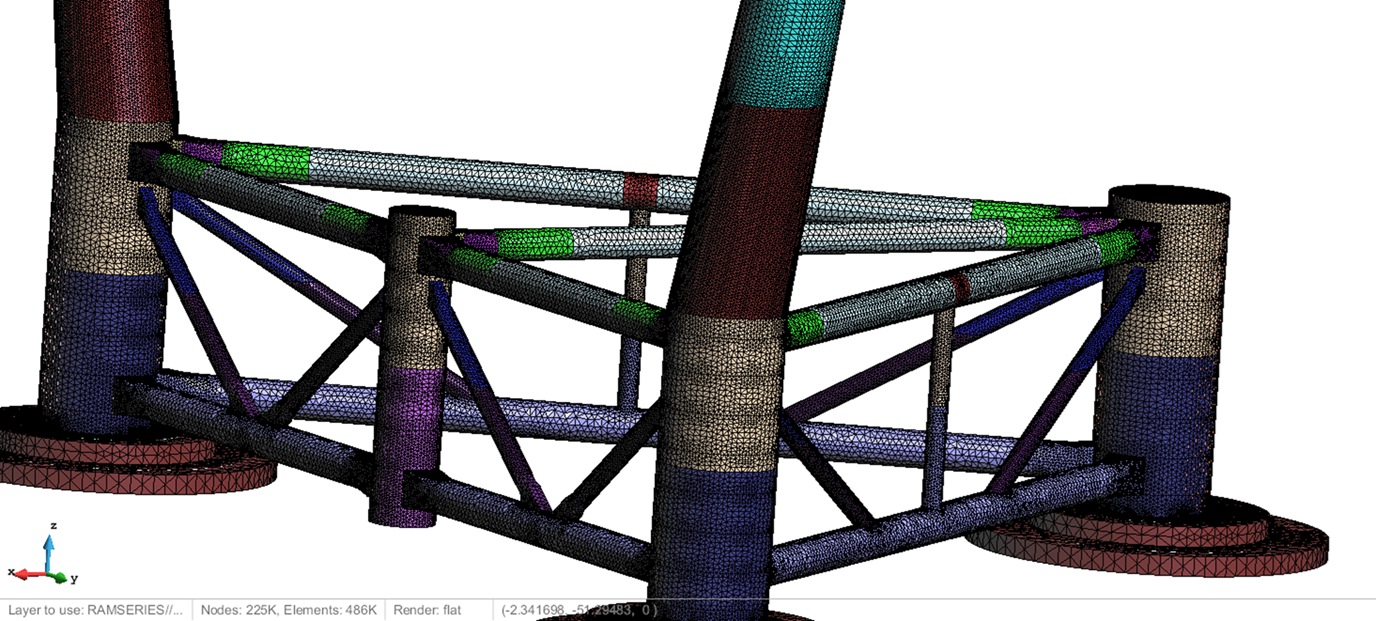

- Computational analysis model (WP3): proposing calculation methodologies for composite materials under cyclic loading.

- Design and calculation of the FRP towers for the W2P prototype (WP4): providing expertise in the design of composite structures.

Application of advanced CAE solutions

COMPASSIS applied its advanced CAE solutions to solve the project engineering ,RamSeries SeaFEM and Tdyn. These CAE solutions made it possible to study and design the different solutions proposed by the partners, providing high added value to the proposals.

Development of aero-hydro-elastic methodology for floating structures.

COMPASSIS has also collaborated in the development of an aero-hydro-elastic methodology, together with CIMNE and UPM, for the analysis of floating structures. This methodology, based on a Modal Reduced Order Model (MMOR), significantly reduces the calculation times of the dynamic behaviour of this type of structure (increasing the speed of the calculation time resolution x1000), allowing the analysis of a large combination of load cases, including the study of fatigue, essential for life cycle analysis and operational decision making for preventive and predictive maintenance.

Commitment to innovation in marine energy

COMPASSIS’ expertise in numerical simulation and engineering has been instrumental in the design of new solutions based on composite materials. The results of the project, which include real demonstrators and technologies ready for adoption in industrial environments, reinforce COMPASSIS’ commitment to applied innovation in the Marine Renewable Energy sector.

A firm step towards the future of offshore platforms

FIBREGY represents a firm step towards the construction of marine energy offshore platforms in composite materials. COMPASSIS is proud to have actively contributed to the technological breakthrough for the European marine renewable energy industry.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement no. 952966.